Takeoff Performance

1 GENERAL

Takeoff Performance tool calculates takeoff performance parameters based on the aircraft manufacturer’s performance algorithms (Manufacturer-provided SCAP modules), operator-specified policies, and applicable regulations. Advanced optimization techniques are used to maximize performance.

The system designed to minimize the occurrence and effects of flight crew error and maximizes the identification and resolution of errors. If user-entered data is not of the correct format or type needed by the application, the EFB do not accept the data. An error message provided that communicates which entry is suspect and specifies what type of data is expected. The EFB system incorporates input error checking that detects input errors at the earliest possible point during entry.

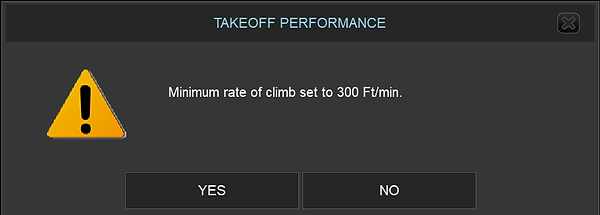

Color-coding philosophies and symbols are used for EFB applications. “Red” color used only to indicate a warning level condition.

“Amber” color used to indicate a caution level condition.

2 BENEFITS

The benefits of takeoff performance tools,

-

Reduce paper in the cockpit, therefore saving weight and reducing clutter,

-

Reduce cost and workload required to update documents,

-

Keep information up to date, enabling easy document revision,

-

Reduce fuel cost through accurate take-off, landing and weight and balance calculations,

-

Engine maintenance cost savings due to reduced thrust settings,

-

Improve safety with onboard performance calculations,

-

Increase payload with real-time performance calculations,

-

Reduce pilot workload,

3 OBJECTIVES

Strongpilot takeoff performance module was developed to fulfill these basic objectives:

-

User friendly standardized module that is same for all aircraft types,

-

Check the consistency and validity of the pilot‘s input and constrain it,

-

Input runway shortening, (Begin/End of runway/Width),

-

Input new obstacle data,

-

Cover customized MEL/CDL items, that effects take-off performance and check the user‘s input of MEL/CDL,

-

Compute and display,

-

optimum configuration/flap setting,

-

automatic lowest Derate setting if applicable,

-

assumed / flex temperature take-off,

-

V1, VR, V2, VREF speeds,

-

N1 / EPR setting, flap/configuration setting,

-

thrust level, flex temperature,

-

acceleration height/altitude,

-

limiting factors,

-

stab trim

4 SUPPORTED AIRCRAFT TYPES

EFB package supports EASA AMC-20-25 / FAA AC120-76 requirements. All data updated via local and/or internet from the server automatically. EFB is based on an open-systems design and provides an integrated operating environment for data sharing hosted EFB applications.

5 TAKEOFF PERFORMANCE BASIS

5.1 CALCULATION STRUCTURE

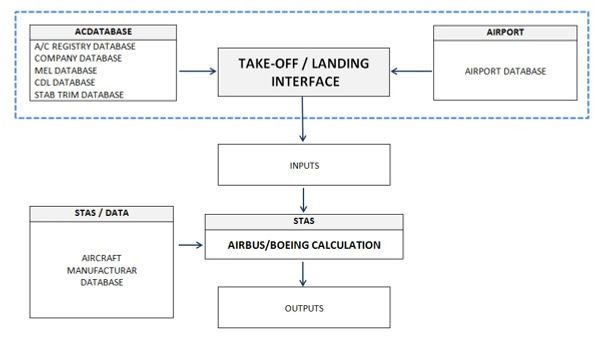

Based on the SCAP (Standard Computerized Airplane Performance) requirements; Strongpilot Takeoff and Landing performance are based on aircraft manufacturer software and databases according to the SCAP standard. Strongpilot will provide both applications on the condition that customer supplies Strongpilot with the aircraft manufacturer software modules and databases, ensuring that all input and output parameters at the modules’ interfaces are handled according to the SCAP standard.

Only these values, supported by the respective SCAP interface, will be displayed by Strongpilot Takeoff and Landing.

Following schematic shows the performance calculation structure.

Not: Airport obstacle database provided by customers.

5.2 CALCULATION METHODS

All performance calculations based on manufacturer SCAP databases except;

-

Stab trim calculation,

-

Some MEL/CDL weight reductions which is not covered in SCAP databases,

-

INFO, CAUTION, WARNING messages.

5.3 PERFORMANCE DATABASES

STM (Strongpilot Takeoff Performance module) uses following databases for calculation.

-

Manufacturer aircraft SCAP database (prepared and maintained by aircraft manufacturer)

-

Airport (Obstacle) database (prepared and maintained by customer)

-

Aircraft registration database (prepared and maintained by software provider)

-

Company aircraft database (prepared and maintained by software provider)

-

Configuration file database (prepared and maintained by software provider)

-

CDL database (Airbus only)

-

MEL / CDL setup database (prepared and maintained by software provider)

-

Stabilizer trim database (prepared and maintained by software provider)

5.4 Use of CWY /SWY

Normally CWY and SWY have been taken into account for performance calculation.

CWY is not used and following INFO message is displayed after calculation when;

-

If CWY is available, and

-

WET or CONTAMINATION selected in Runway Condition Menu

5.5 LINE UP ALLOWANCE

Loss of runway length due to alignment. Alignment distance depends on the airplane geometry and access possibility to the runway in use.

The takeoff distance adjustment is based on the initial distance from the main gear to the beginning of the runway since the screen height is measured from the main gear. The accelerate-stop distance adjustment is based on the initial distance from the nose gear to the beginning of the runway.

STM applies Lineup corrections automatically according to the selected runway in takeoff performance. Allowance value is displayed in DETAIL section after calculation is completed.

5.6 USER PREFERENCES

Allows predetermine of the defaults for program execution, such as weight and temperature units, distance units, etc.

Choose your unit preferences using the buttons for each of the selections.

Default setup of preferences are shown in the following picture.

5.7 TRACKED DATA LOGS

Takeoff performance calculation results are kept in memory for further research or investigate. These tracked data are sent to the dedicated server automatically when internet connection is available.

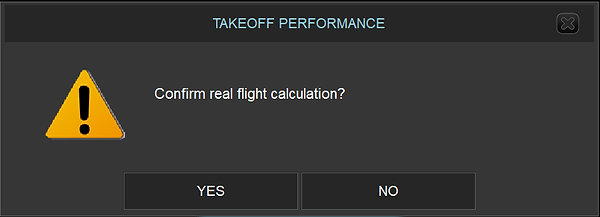

Pilot may decide the which calculation is the final for real flight.

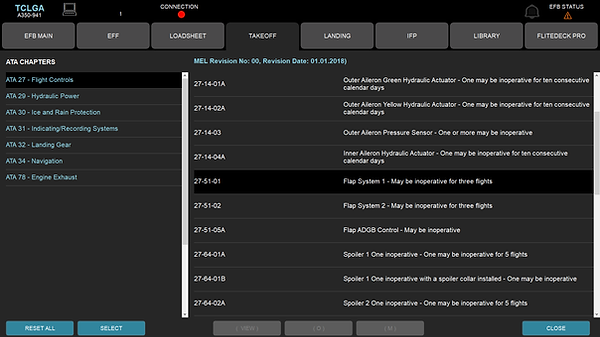

5.8 MEL/CDL ITEMS

Performance tool uses a database to maintain all the performance-related Minimum Equipment List (MEL) and Configuration Deviation List (CDL) penalties.

Please note that only those MEL or CDL items are shown which affect the performance calculation. MEL or CDL items which do not influence the performance calculations are not listed.

One simply clicks on the MEL or CDL button on performance tool displays the MEL/CDL selection screen.

Following illustration shows CDL 27-02 box clicked in the CDL screen for selection.

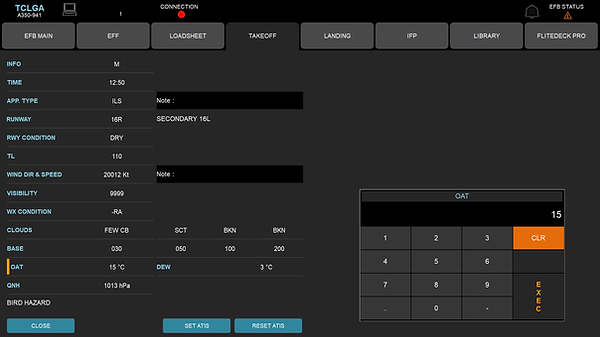

5.9. ATIS ENTRY

Required inputs for performance module like runway direction, runway condition, wind direction & speed, OAT and QNH may be entered directly from main performance GUI.

In addition, ATIS form is designed to keep and set all ATIS information to performance tool via separate window. When recorded, data(s) may be set to takeoff performance tool by pushing SET ATIS button from ATIS form.

5.10 INFO / NOTAM

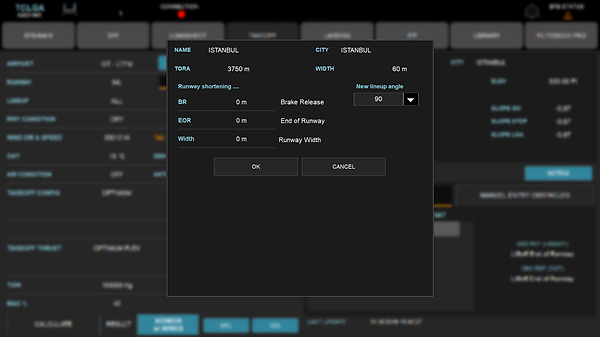

Software has the capability to introduce NOTAM' s and/ or shortening into the takeoff calculation. This added Notam does not store in the database.

The information on this screen is defined by the following:

BR

The distance that the runway is to be shortened from the start of the takeoff roll in the units specified at the right side of value.

EOR

The distance that is to be taken from the liftoff end of the runway in the units specified at the right side of value.

Width

The distance that is to be taken from the width of the runway in the units specified at the right side of value.

5.11 DATABASE INFO

All database versions and some of the Aircraft limits which are used in calculation is listed in DB INFO page.

5.12 A/C AVIONIC DATA COMPARISON

Data Disagree Check (Aircraft UDP server is available)

Flight manager checks calculated takeoff data and entered takeoff data to the FMC automatically.

System gives popup message if any data differs.

Following data cross checked for disagree condition.

-

Selected Flap/Config

-

V1, VR and V2

-

EO Acc Alt